Ultra high performance concrete is a cutting-edge construction material worthy of its name. While concrete has long been hailed as a durable material, it has weaknesses. Years of advancements have led to the development of UHPC, surpassing regular concrete’s qualities.

Ultra high-performance concrete, also known as UHPC, is an advanced type of concrete that exhibits exceptional strength and durability more than conventional concrete. It consists of fine powders, fibers, and other specialized ingredients, forming a material with remarkable durability and mechanical properties.

Ultra high strength concrete is unique and composed of a key differentiator. Traditional concrete usually contains cement, water, and aggregates, which are typically composed of sand and gravel. Some traditional concrete forms also use supplementary materials such as silica fume and fly ash.

In contrast, UHPC contains a high volume of fine particles, such as silica fume, and can also include steel and synthetic fibers. This combination gives UHPC its notable strength and durability.

Some people confuse UHPC with GFRC, which stands for glass fiber reinforced concrete. While both are advanced building materials, they have differing compositions and applications.

Ultra high performance concrete mix design involves components such as silica fume, quartz flour, fine silica sand, cement, water, and optional fibers. UHPC uses very fine particles, which provides for a denser consistency. In comparison, GFRC’s main components include cement, polymers, sand, and glass fibers. Glass fibers are the defining feature of GFRC, as its name suggests, resulting in better tensile strength.

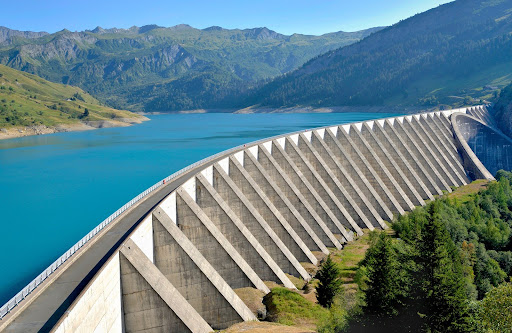

In terms of applications, UHPC is better suited for structural elements and high-performance construction. Contractors use it in projects that demand high strength and durability, such as bridges and dams. On the other hand, GFRC is more flexible, making it better suited for architectural cladding, ornamental applications, and even furniture.

Ultra high-performance concrete has two defining characteristics: strength and durability.

Have you ever asked, “What is the strongest concrete?” UHPC is certainly a contender. One of the most notable features of UHPC is its exceptional strength.

Traditional concrete generally has a compressive strength range of 20 to 40 megapascals (MPa). In contrast, UHPC can achieve compressive strengths exceeding 150 MPa. This extraordinary strength makes UHPC ideal for applications where structural integrity is paramount.

UHPC is also incredibly durable, demonstrating freeze/thaw resistance, abrasion resistance, and chloride permeability.

UHPC is extremely resistant to the freeze/thaw cycle, making it perfect in colder climates. Traditional concrete may deteriorate over time due to the expansion of water within its pores during freezing. UHPC’s dense matrix minimizes water penetration, reducing the risk of freeze/thaw damage.

The abrasion resistance of UHPC is significantly higher than that of traditional concrete. This makes it an excellent choice for structures exposed to abrasive forces, such as industrial floors, bridge decks, and pavements.

UHPC offers low chloride permeability, essential for structures in marine environments or those that frequently come into contact with de-icing salts. This characteristic helps prevent the corrosion of embedded reinforcing steel, extending the structure’s lifespan.

Here are the most common applications of UHPC.

Ultra high-performance concrete panels are durable and versatile, making them popular for new building constructions. You might find UHPC panels used in facade cladding due to their easy installation and longevity.

The exceptional strength and durability of UHPC make it an ideal material for the construction of dams and docks. Its resistance to water permeability and freeze/thaw cycles ensures the longevity of these critical structures, even in harsh environmental conditions.

UHPC is widely used to construct marine structures such as bridges, piers, and offshore platforms. Its chloride penetration and abrasion resistance, coupled with high compressive strength, makes it well-suited for saltwater environments. These qualities minimize the effects of corrosion as well as mechanical forces.

Airports demand robust and durable construction materials to support heavy loads and frequent traffic. UHPC is utilized in airport runways, taxiways, and aprons due to its high compressive strength, abrasion resistance, and capacity to withstand heavy loads.

Parking structures face constant wear and tear from vehicular traffic. Fortunately, UHPC’s enhanced abrasion resistance and compressive strength contribute to the longevity and safety of parking structures.

UHPC is more resistant to chemical exposure than traditional concrete, making it perfect for treatment plants. These plants often use this material to build the facility’s tanks, basins, and other critical components.

UHPC is a common fixture in railway infrastructure, including tunnels and bridges. As mentioned above, UHPC can withstand heavy loads and resist high impacts – two things that moving trains surely bring. UHPC supports the safety and longevity of railway structures.

Industrial floors often experience heavy traffic from people and machines. In certain industrial facilities, chemical exposure is also a possibility. UHPC’s resistance to abrasion and low-maintenance requirement, make it suitable for these types of floors.

Pre-bagged UHPC tends to go for $2,000 per cubic yard, with additional fibers costing $250 to $500 per cubic yard. Compared to traditional concrete, ultra high-performance concrete is certainly costly. However, its great qualities make up for its high price tag. Additionally, efforts are underway to develop more affordable UHPC.

Ultra high performance concrete is certainly a big leap forward in construction. Its exceptional strength, durability, and resistance to various environmental factors make it a preferred choice among contractors and construction companies. Plus, its wide range of applications contributes to its versatility.

RELATED ARTICLES: